List of products

Files to download

Technical data sheet PWM

Pictures

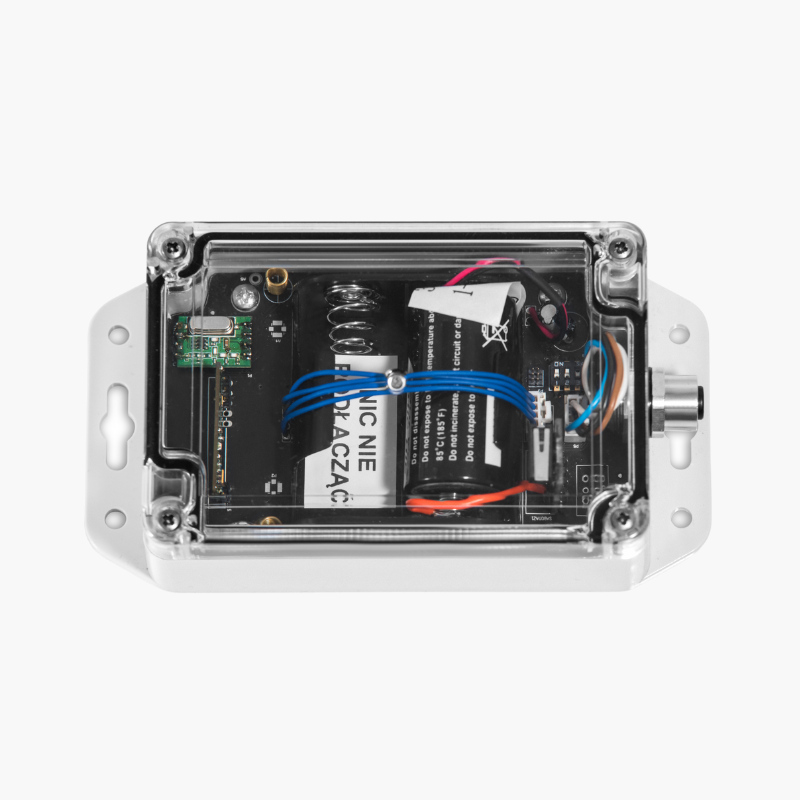

PWM

Professional Wireless Modul – dedicated to the PTA terminal

Many years of practice in the implementation of telematics solutions in semi-trailers have revealed to us a problem related to the high level of complexity of the performed installations. This applies in particular to implementations where additional information is obtained, such as opening the loading door or measuring the temperature in the cargo space.

The number of labour hours needed for the professional installation services generates high costs, while greatly extending the implementation time. This causes many problems for logistics departments, which are forced to suspend transport for a long time.

To meet these problems, we have created PWM – a wireless input module that allows you to transmit information via radio to the PTA terminal.

Professional Wireless Module (PWM) is a battery-powered wireless device that allows you to obtain additional information from the trailer and send it to the PTA terminal. PWM performs the following functions:

- two independent inputs enabling the connection of various information signals (e.g. reading information from the rear and side opening sensor of the cargo door),

- temperature measurement supporting information from two independent thermometers,

- control of the battery charge level,

- control of the humidity level in the housing,

- control of the opening of the housing,

- full compatibility with PTA terminal.

Using two-way wireless communication on the 868.35MHz PWM band, it ensures 100% efficiency of data transmission to the PTA terminal, regardless of the type of the carried cargo and the level of filling the cargo space.

Information obtained from the radio link by the PTA terminal is forwarded according to the programmed configuration (more in the technical data sheet of the PTA product).

The PWM kit is:

- Motherboard designed from scratch by our engineers.

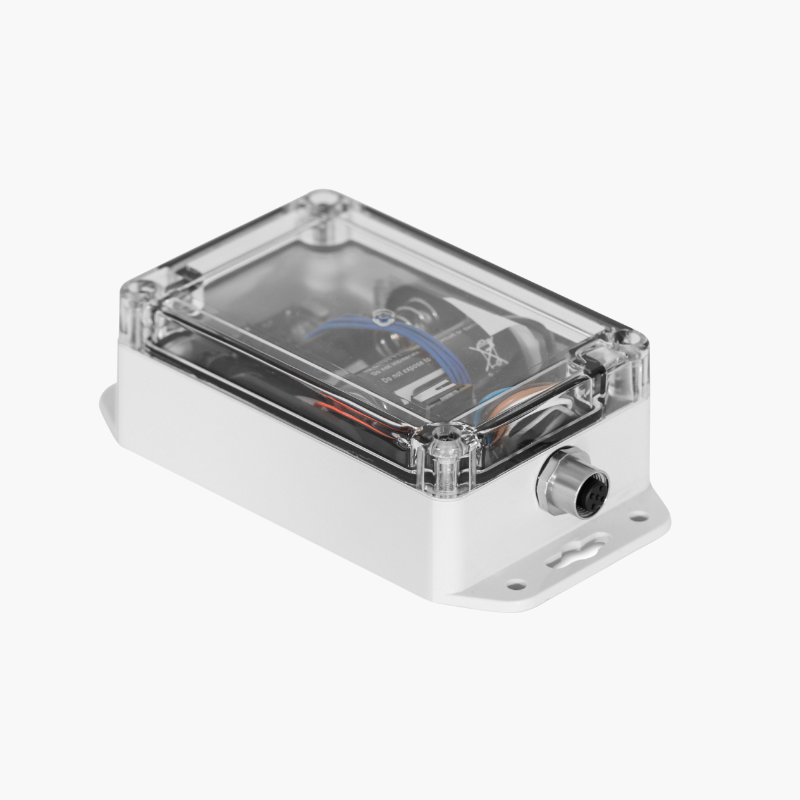

- Hermetic plastic housing that meets the necessary requirements for proper operation of electronics in unfavorable conditions in semi-trailers.

- A specialized industrial connector built into the body of the housing for connecting signals from additional sensors.

- Connecting cable with a built-in thermometer included in the set.

- Battery power supply designed for operation in low temperatures: 2x1.5V or 1x3.6V.

- Average current consumption tested with the following assumptions:

- two thermometers connected,

- permanent broadcasting every 10 minutes,

350,8 µA +/- 5%.

- Operating temperature from -30⁰C to +70⁰C.

- 2 NO or NC inputs controlled by radio link ground.

- 2 temperature measurement inputs, reading range from -55⁰C to +85⁰C.

- Internal humidity sensor (electronic status control).

- Two-way radio line 868.35MHz.

- Plastic housing: ABS-PC.

- Dimensions:

- height: 46mm,

- width: 152mm,

- depth: 82mm.

- Sealing class: IP67.

- Weight without batteries: 230 g

- Plastic housing with mounting eyelet, ABS - polycarbonate.

- IP67 tightness class.

- Increased resistance to mechanical damage.

- Industrial connection socket (1 pc.) ensuring IP67 tightness and high mechanical resistance.

- Housing opening controlled by an internal sensor always generates an alarm (regardless of the alarm arming status). Opening without generating an alarm is possible after entering the PTA terminal into service mode.

- Internal humidity control provides instant feedback in the event of moisture (leakage).

- Supports one 3.6V industrial LI-150 battery or two standard 1.5V LR14 batteries.

- As standard, a 3.6V LI-150 battery with a capacity of 8500mAh is used, adapted to work in low temperatures.

- Commercially available LR14 batteries allow the user to easily replace a discharged battery in an emergency.

- Industrial LI-150 battery adapted to work in low and high temperatures: from -55⁰C to +85⁰C.

- Continuous monitoring of battery consumption (information sent to PTA).

- Low battery alert (information sent to PTA).

- INPUTS

- CW_01: Auxiliary input …………………………………………...........................................………………………………....…….…… [NO-;NC-]

The alarming function depends on the setting in the PTA control panel. - CW_02: Additional input …………………………………………...........................................………………………………………… [NO-;NC-]

The alarming function depends on the setting in the PTA control panel - CW_03: PWM case opening tamper, internal sensor ……………………………..............................................………[NC-]

- T3 [M_03] – additional thermometer.

- T4 [M_04] – main thermometer built into the radiolink connection plug.

- CW_01: Auxiliary input …………………………………………...........................................………………………………....…….…… [NO-;NC-]

Information passed as a high state of the emulated physical input.

- PW_01: Alarm of exceeding the allowed humidity in the PWM housing. By default, the alarm is generated by the humidity level exceeding 75%.

- PW_02: PWM module battery low.

- PW_03: No communication with thermometers.

The status of communication between the radio link and the alarm control panel is signaled by built-in PWM flashing LEDs (e.g. no communication - red color).

PWM as standard sends information to the PTA in an asynchronous manner when the state of the input lines changes. In addition, every two hours a control message is sent confirming the correct communication between PWM and PTA. The loss of communication is signaled by the control panel by sending information to the server receiving the data.

If temperature measurement is connected, PWM activates an additional communication mode by sending data to PTA every 10 minutes by default (time programmable via PTA).